Double Side Silicone Coated Polyester Films Paper Slitter Rewinder

1800mm Jumbo Silicone Coated Paper Slitting Rewinding Machine Technical parameter Use This machine suitable for a lot of

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | HC-Z1300/1600/1800 |

| Classification | Ultrasonic Label Cutting Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Paper |

| Packaging Material | Wood |

| Automatic Loading | by Hydraulic |

| Web Guide | Ultrasonic Correction |

| Loading Section | 3"+6" Mechanical Check, Shaft Less Loading |

| Unloading Mode | Automatic Unloading Via Chain |

| Certification | CE, SGS |

| Slitting Knife | Korean Brand Circular Knives |

| Automatic Metering | Korea Autonics |

| Control System | Germany Siemens PLC |

| Precision | 0.03 mm |

| Unwinding Section | Separated Unwinding Section |

| Drive System | 3 Servo Motor (4kw+11kw+11kw) |

| Unwinding Diameter | 1200mm |

| Rewinding Diameter | 1000mm |

| Speed | 300 M/Min |

| Transport Package | Pallet |

| Specification | 4500*3200*2000 mm |

| Trademark | LOYAL |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 100 |

Product Description

1800mm Jumbo Silicone Coated Paper Slitting Rewinding Machine

Technical parameter

| Machine model | HC-Z1300 | HC-Z1600 | HC-Z1800 |

| Slitting effective width | 50-1300mm | 50-1600mm | 50-1800mm |

| Slitting speed | 50-300m/min | 50-300m/min | 50-300m/min |

| Unwinding roll diameter | Φ1200mm | Φ1200mm | Φ1200mm |

| Rewinding roll diameter | 2*Φ1000mm | 2*Φ1000mm | 2*Φ1000mm |

| Main servo motor | 4kw | 4kw | 5.5kw |

| Rewinding servo motor | 11kw*2 | 11kw*2 | 11kw*2 |

| Power supply | 380V, 3 three-phase, 50hz | 380V, 3 three-phase, 50hz | 380V, 3 three-phase, 50hz |

Use

This machine suitable for a lot of paper, such as 40g-400g/m^2 no carbon paper,film paper ,coated paper, adhesive sticker etc. jumbo roll slitting &rewinding machine.

Characteristic

- PLC control, automatic tension control.

- 3 servo motors control, central surface rewinding

- Frequency converter timing for main machine, keeping speedup and stable operation.

- It has the functions of automatic metering, automatic alarm, automatic stop by setting length you need.

- Rewinding adopts the A, B air expansion shaft structure.

- Unwind frame automatic lifting up and down by chain, unloading safe and conveniently.

- Shaft less automatic loading by hydraulic

- Shear knife automatic slitting device for waste edge scraping (Blower exhaust waste).

More details of 1800mm jumbo silicone coated paper slitting rewinding machine

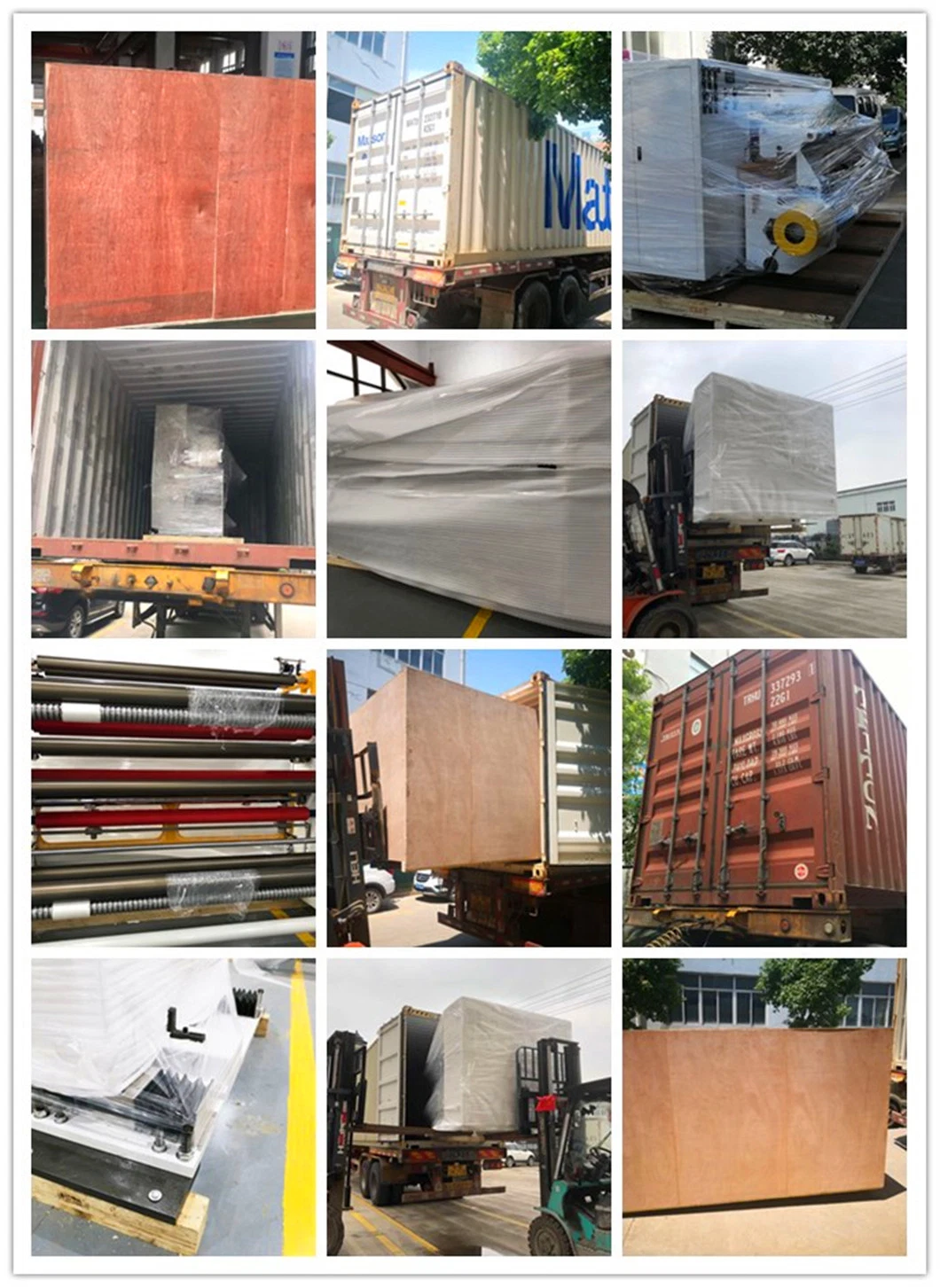

Packing and shipping

Lastest exhibition

Why us

------R&DLoyal engineers focus on the innovation of the slitting machine continuously.We combine powerful construction and aesthetic characteristic while maintaining the highest standard of quality.------QAIn order to supply products of high consistently high quality and reliability, Loyal staff strengthens Quality Assurance protocols and procedures as important part of overall quality, safety management.------DetailCare about every detail to improve our dear customers' operation efficiency and convenience.------After-sale serviceLoyal team will respond to clients' inquiries or questions within 24 hours.

Contact us without hesitation! We are willing to send you in greater detail!